Description

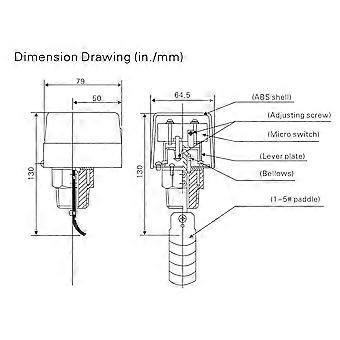

Features:100% brand new and high qualityThe product is used to measure the dynamic state of the liquid flowing through the pipeline, such as: water, ethylene, ethylene glycol and other liquids that have no corrosive effect on copperApplication: water treatment system, central air conditioning, water cooling unit, fire protection system and other fields.Adopts premium material, with strong temperature adaptability of 0~ 120, and can withstand high pressure of 1.0Mpa.The flow control value is adjustable and the action repetition point is stable.Specification:Material:brass and stainless steel(body), stainless steel( Leaf blade), plastic (shell)Interface dimensions: 1/2"(HFS-15)Control mode: blade typeMax. working pressure: 1.0MpaAmbient temperature: 0C~60Liquid temperature: -10~100(non-freezing)Micro switch: single pole double throw (SPDT)Contact life: 100, 000 cyclesElectrical parameters of micro - switch: 220VAC, 15AWeight: Approx.407g/14.4ozPackage list:1 x flow switch1 x Chinese and English operation manual3 x paddleInstallation and adjustment:1. Open the flow switch housing;2. The switch has been set at the minimum flow value when leaving the factory. Increase the flow setting value and turn the adjusting screw counterclockwise;3. Press the target to check whether the micro switch can work normally. Excessive clockwise rotation of the adjustment screw may lead to the failure of the flow switch;4. After the installation, please press the lever of flow switch several times to check. Once it is found that there is no "click" sound when the lever is restored, rotate counterclockwiseAdjust the screws until there is a "click" sound;5. The adjustment screw of lacquer seal is only for factory to adjust the state of flow switch. Please do not change or adjust it6. Observe three working cycles, make sure that the switch and the system connected with it are in normal operation, and cover the switch shell in time.Matters needing attention:1. Please check the flow switch carefully before installation. The package should be complete and the appearance should be free from damage and deformation. If you have any questions, please contact the manufacturer:2. The flow switch can be installed in the horizontal pipe or the vertical pipe with the upward direction of liquid flow, but it cannot be installed in the pipe with the downward direction of liquid flow. Gravity should be considered when installing in piping above the flow direction of the fluid3. The flow switch must be installed on the straight pipe of the section, both sides of which are short of the straight stroke of 5 letter pipe diameter. At the same time, it should be noted that the direction of liquid flow in the pipe must be consistent with the direction of arrow on the switch shell.4. The HFS flow switch shall not be used in pipelines where the liquid temperature drops below the freezing point of the liquid. 5. The HFS flow switch cannot be hit by water. If there is a quick closing valve in the downstream of the flow switch, the throttle must be used.6. When installing wiring, please pay attention to the following matters:* it is absolutely forbidden to impact the wrench on the switch bottom plate, resulting in deformation failure of the flow switch;* to avoid electric shock and damage to the equipment, cut off the power supply when wiring or debugging;* when wiring, it is absolutely forbidden to adjust any screws other than micro switch terminals and grounding screws. It should be noted that the micro switch wiring cannot be usedIf the force is too strong, it will easily cause the position displacement of the micro switch itself and lead to the failure of the flow switch.* special grounding screws must be used for wiring, and installation screws cannot be removed at will, otherwise the controller will be deformed and invalid;* the blade of the flow switch cannot contact with the inner wall of the pipe and other throttles in the pipe, otherwise the switch cannot be reset normally.

-

Fruugo ID:

426049127-894819509

-

EAN:

7313854265178

Product Safety Information

Please see the product safety information specific to this product outlined below

The following information is provided by the independent third-party retailer selling this product.

Product Safety Labels

Safety Warnings:

Warning: Please read the product instructions carefully before use to ensure correct use.

Serial Number:

7313854265178

Delivery & Returns

Dispatched within 2 days

Shipping from China.

We do our best to ensure that the products that you order are delivered to you in full and according to your specifications. However, should you receive an incomplete order, or items different from the ones you ordered, or there is some other reason why you are not satisfied with the order, you may return the order, or any products included in the order, and receive a full refund for the items. View full return policy